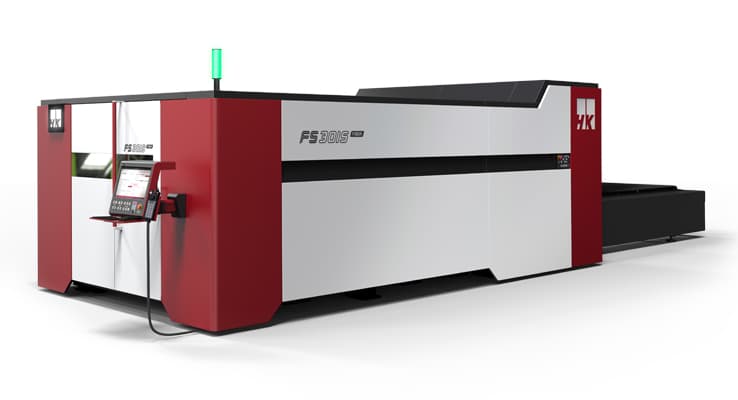

Fiber Laser Cutting Machine Taiwan

The beam quality is lower than 1.5 M2 for the 20W or 30W lasers, while it's less than 1.8 Mi2 for the 50W laser.

Plasma can, however, cut any type or metal up 80mm thick or 3 inches thick. Plasma can start cutting quicker than laser when cutting thicker material.